Behaviour Safety (BBS)- OIAC Tool

Behaviour-Based Safety (BBS) OIACTM, is often described as a bottom-up approach (frontline employees), with top-down support from safety leaders. The behavior safety approach promotes interventions that are people-focused and often incorporate one-to-one or group observations of employees performing routine work tasks, setting goals carefully, and giving timely feedback on safety-related behavior, coaching, and mentoring.

CLIDE BBS OIAC Model

Safety perception survey helps in understanding that what people believe and how they behave are directly related to one another. CLIDE perception survey will both quantify what employees perceive and identify the gap between the beliefs of the workforce and those of management. The survey report can be used to develop a road map for recommended changes make changes to current policies and procedures make improvements in current be used to develop a road map for recommended changes make changes to current policies and procedures make improvements in current practices and create the framework for a long-term safety strategy.

BBS Online Courses

Learn how to implement BBS in an organization, by understanding how to frame the implementation strategy, challenges, and barriers during implementation, criteria for selecting activities, and behavior data analytics.

Enroll now and start learning

Implementing BBS BBS Observation

CLIDE Strategy Insights

What result you can expect? Case Study

Our BBS OIACTM work leads to tangible goals and ready-to-launch initiatives to achieve them. As an example, one company we helped through such a BBS OIACTM process targeted–and achieved–these concrete objectives:

71%

Increase in safe behavior

73%

Reduction in barriers for creating a sustainable safety culture

63%

Increase in employees engagement in safety activities

89%

Down trend in incident rate throughout the organization

Example of our work Case Study

Case study – Behavior-Based Safety Reduces Lost Days at a Bulk Drug and API Facility

CLIDE assisted in the implementation of a Behavior-based safety OIAC process for manufacturing plants with 1700 employees at a bulk drug and API facility that produces drugs for its client.

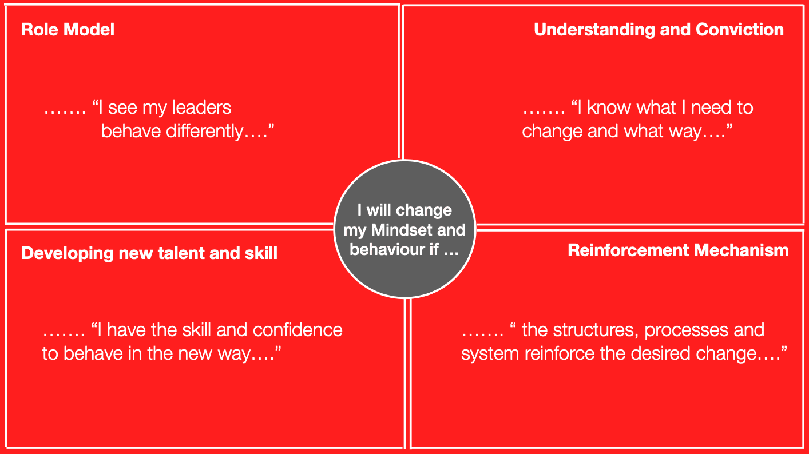

Influencing Mindset and behaviour change model

BBS Training by number Testimonials

76

Top companies is our client

20

Program conducted in each company

95%

Feedback rating for our program

Read about the Behaviour Change Model

Free insight on how to bring behavior change

Our Approach

Defining a bold vision for how the company must change, based on analysis of its present state, now and in the future

Where do we stand at present?

Where do we stand at present?

Together, we assess the company’s current state in the context of the maturity model, gauging how far its business model must shift to sustain or need change. Understanding this point of start—and envisioned point of arrival—will establish the magnitude, diculty, and velocity of the change.

What is the right choreography?

What is the right choreography?

We look across the seven-levels to craft right BBS implementation strategy — leadership, safety beliefs, organizational values, safety competency, observation data, workforce involvement and safety KPIs—to establish the most logical sequence of action. The goal is to pull the right gear at the right time, without disrupting the company’s overall strategy.

What tools should be used?

What tools should be used?

Crafting a BBS implementation plan is one thing, but executing it effectively requires the right leadership framework and the digital tools for data analysis. The organization have achieved the best result by using.

By Numbers (Industry Served- Oil, Gas, Pharma, Steel, Construction, Shipyard, Power)

11

Consulting Projects

704

Training Conducted

> 3 Yrs

Project Duration

2

Digital Tools

Esteemed Clients

CLIDE Strategy Insights

Successful Implementation of Behavior-Based Safety (BBS) in the Steel Industry

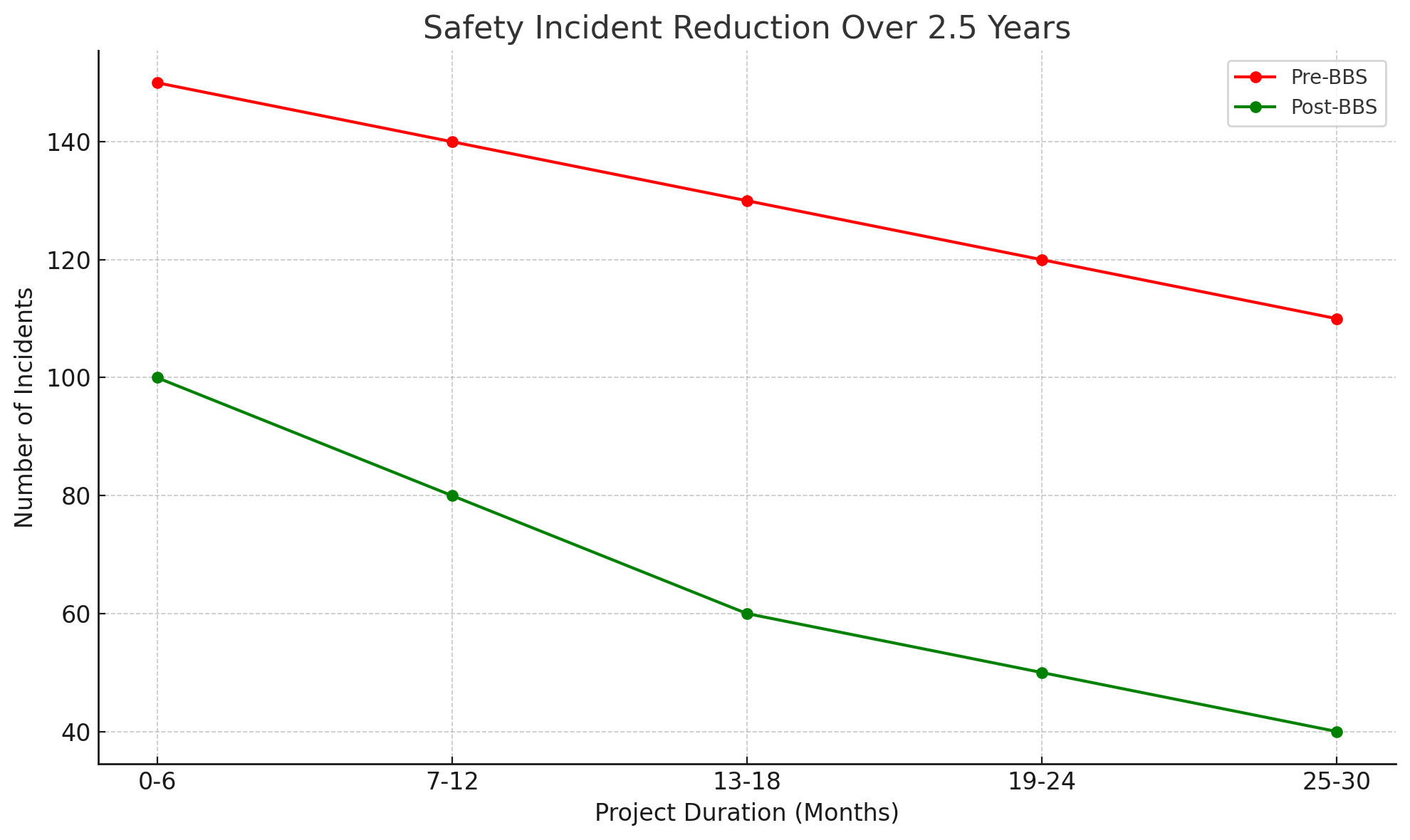

In the complex and high-risk environment of the steel industry, safety is a critical concern. Our client, a leading steel manufacturer, sought to enhance workplace safety through the implementation of a Behavior-Based Safety (BBS) program. With over 5,000 employees working across multiple sites, the primary goal was to reduce incident rates and create a sustainable safety culture by targeting unsafe behaviors.

This case study outlines the structured approach taken to implement BBS over 2.5 years.

Behavior-Based Safety Program

Unlock a Culture of Safety Through Behavior-Based Safety Training

At CLIDE, we are dedicated to helping organizations foster a proactive safety culture that empowers employees to take responsibility for their actions and environment. Our Behavior-Based Safety (BBS) Training Program is designed to equip your team with the skills and mindset to prevent accidents and promote a safer workplace through observable behaviors and positive reinforcement.

Talk to our consultant to know about our BBS OIAC Process.

Join us and make your company a safer place.